position: HOME > PRODUCTS > CNC Cutting Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

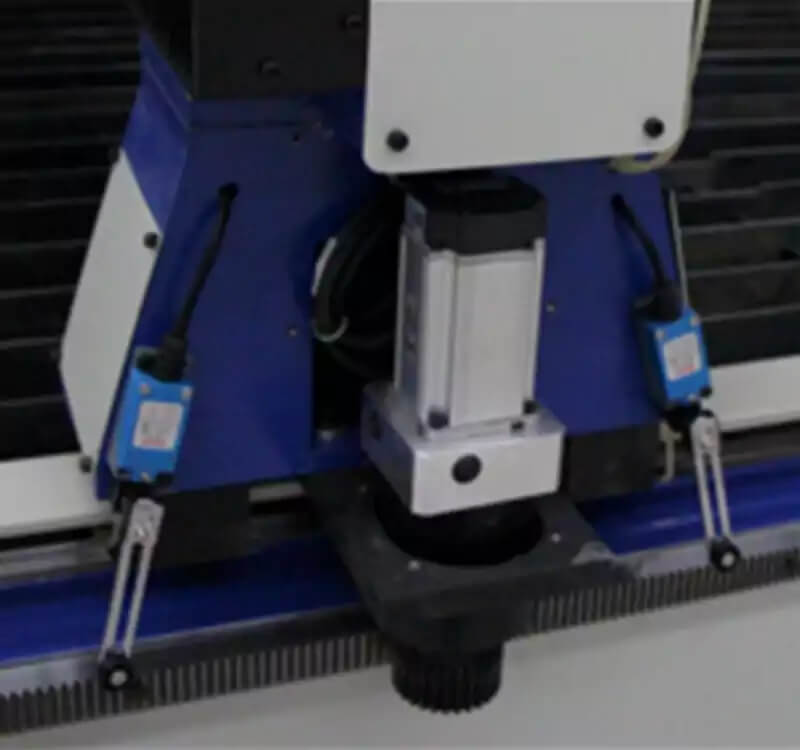

1. The whole machine adopts a bench-top welded structure, which is driven on both sides. The track base is made of 80 * 25mm high manganese steel plate through precision machining. The rack and pinion are all quenched, which greatly improves the toughness and hardness of the running parts. All quenching and fine grinding parts are treated with imported chemical antirust oil, precision tooling automatically matches and meshes. It has the characteristics of high strength, high precision, and not suitable for deformation.

2. Beams, linear guides, and all moving structural parts are made of alloy precision casting and precision milling, which has the characteristics of high strength and light inertia. Double-axis wear-resistant load-bearing guide. A four-bearing maintenance-free slider module is standard. High speed, fine, stable, durable.

3. The dust removal and exhaust system are equipped as standard, adopting shallow water stainless steel sink or dust removal air curtain to remove smoke and dust. Keep the site environment clean to prevent pollution emissions.

4. The F2300 numerical control system adopts an advanced numerical control system developed by Shanghai Jiaotong University, which can automatically convert and generate cutting programs, and the operation is very simple.

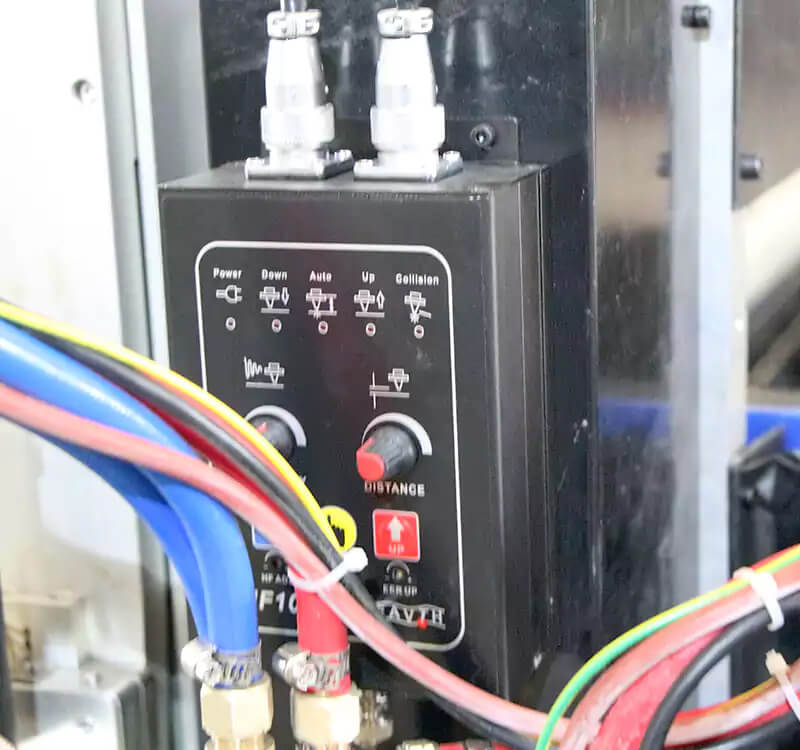

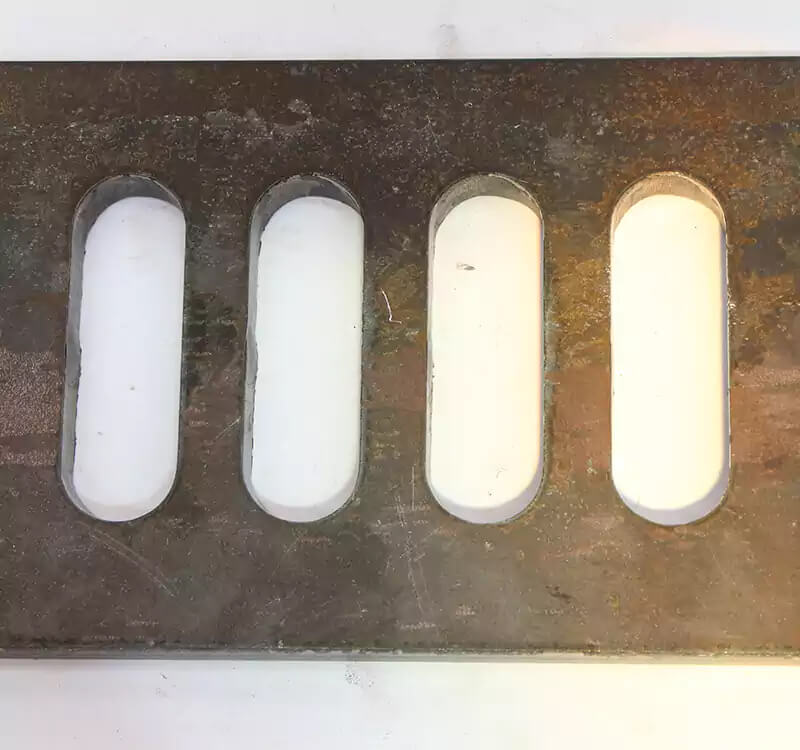

5. It can cut through 0.5mm-30mm perforation, and cut 40mm metal material on the edge. It adopts cool methods such as air cool and water cool and is equipped with imported metal cutting torches as standard, which completely solves the problem of easy burnout of the cutting torch. With built-in arc pressure adjustment, kerf compensation, arc extinguishing return, anti-collision system, it can work continuously for 24 hours.

6. Digital control of the driver, optional Japanese Panasonic servo motor and driver, walking self-feedback system, strong anti-interference, and fast response speed, high running accuracy, closed-loop control without losing steps, long service life.

Main features of desktop flame CNC cutting machine:

1. Desktop gantry structure, dual drive servo control, good stability;

2. Horizontal effective stroke 20000mm, vertical effective stroke customized;

3. The torch fires automatically;

4. Optional plasma or flame plasma;

5. Suitable for cutting within 2 meters of steel plate width;

6. Select CNC system from Beijing Start or Shanghai Fangling;

7. Optional expert nesting software, with co-edge, bridging function;

8. Flame perforation cutting 5-150mm carbon steel, 150mm edge, cutting speed can reach 0.5 meters per minute;

9. Plasma cutting thickness depends on the plasma power source. Plasma cutting speed is 2-4 times of flame. Plasma cutting is recommended to 20mm;

10. The plasma power supply can use a domestic first-line brand or imported power supply. Plasma power processing has a large difference, which has a great impact on cutting quality.

Technical parameter:

| Model No. | 1530 | 1840 |

| Cutting effective width (mm) | 1500 | 1800 |

| Total width (mm) | 2000 | 2400 |

| Cutting effective length (mm) | 3000 | 4000 |

| Total length (mm) | 4000 | 5000 |

| Numerical control system | American Haibao System or Shanghai Jiaotong University System or according to your choice | |

| Plasma power supply | American brand name or according to your requirements | |

| Cutting thickness | Depending on the power supply you choose | |

| Cutting table | Normal worktable or dedusting table can be selected | |

Machine Accuracy:

| 1. Installation accuracy of guide rail: | |

| 1) Straightness accuracy of main rail | ±0.2mm / 10m |

| 2) levelness between two rails | ±0.5mm/10m |

| 3) Longitudinal levelness of main rail | ±0.2mm/m; ±2mm/ overall length |

| 4) Parallelism between two rails | ±2mm/ rail space |

| 2. Machine accuracy: | |

| a. Longitudinal effective stroke | >nominal size 20mm |

| b. Transverse effective stroke | > nominal size 10mm |

| c. Linear positioning accuracy | ±0.1mm/10m (1000×1000mm Comprehensive graphics detection) GB deviation≤±0.3mm |

| d. Linear repeat accuracy | ±0.4mm/10m |

| e. Torch stroke | ≤170mm |

| f. Cutting speed | ±5% of setting speed |

| g. Automatic lifting precision | ±0.5mm |

| 3. Comprehensive machine precision: | |

| a. Length deviation(four sides) | 0.3mm |

| b. Diagonal deviation | 0.3mm |

| c. Back to the origin of the deviation | 0.2mm |

| d. Diagonal straightness accuracy | 0.3mm |

| e. Intersection deviation | 0.3mm |

| f. Linear deviations | 0.2mm |

| g. Entire machine positioner precision | 0.1mm |