position: HOME > PRODUCTS > Welding Positioner

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

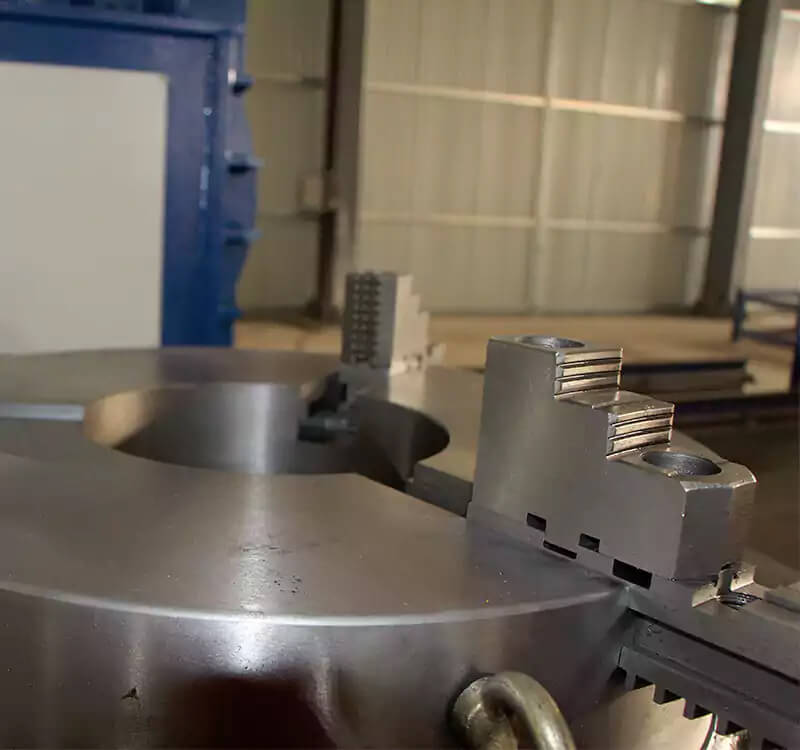

The numerical control L type pipe rotating welding positioners adopts an L-shaped structure, which has good openness, suitable workpiece clamping height, convenient welding operation, and is suitable for structural parts with a large number of weld positions. When welding, the welding seam is in the optimal position, avoiding the overhead welding and vertical welding, ensuring the welding quality, and changing the welding position according to the welding seam requirements of the workpiece.

The welding positioner guarantees safety during the welding and turning of the workpiece reduces the labor intensity of the operator and improves labor productivity. Rotating, turning and lifting all adopt high-precision AC servo drive system, which can accurately position the workpiece and ensure the position accuracy of the workpiece in space.

Features:

1. The structure of the whole machine adopts a precision machining table, which has a long service life; the frame is formed by tailor welding of plates and profiles and is annealed after welding to have sufficient mechanical strength and ensure that it will not be deformed for a long time. The slewing mechanism and the turning mechanism are mounted on the frame through bearings and precision slewing bearings.

2. The slewing bearing is a heavy-duty precision slewing bearing with high bearing capacity, small backlash, and a large design margin, to reduce the amount of axis runout after the workpiece is turned over and ensure position accuracy. The rotating pinion gear, the turning pinion gear, and the supporting external teeth respectively adopt special backlash-free toothing structures.

3. Servo motor shaft and precision reducer (Nabotsk precision RV reducer in Japan, with stable performance and no noise throughout the year) The shaft hole adopts a direct connection structure, which has high transmission accuracy.

4. Reliable quality, reasonable price, and support for customization. The chuck diameter can be customized according to the diameter of the welding workpiece of the user. It can be used with the robot, and can also be equipped with various positioners according to your requirements.

Technical parameters:

| Model | LHB-5 | LHB-10 | LHB-20 |

| Rated input voltage frequency | Input three phase current:200V 50/60Hz | ||

| Input lading range | Input three phase current:200V±10% | ||

| Max lading weight(kg) | ≤500 | ≤1000 | ≤2000 |

| Rotatring speed(r/min) | 0-3 Servo regulate | ||

| turning speed(r/min) | 0-3 Servo regulate | ||

| Rotatring angle(°) | 360 Infinite rotary | ||

| turning angle(°) | ±90 | ||

| Rotatring power (KW) | 0.75 | 1.5 | 3 |

| turning power(KW) | 0.75 | 1.5 | 3 |

| Repeat positional accuracy | Less than ±0.2 | ||

| Table size(mm) | 600 | 800 | 1000 |