position: HOME > PRODUCTS > CNC Cutting Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

CNC plasma and flame square tube cutter adopt a horizontal structure and the body is made of cast iron. It is a kind of equipment for automatic calculation and cutting of the rectangular tube end joint of the other tube. It can adjust the center, cut the channel steel, angle iron, oval tube, and other materials. The CNC plasma and flame square tube break through the previous era of irregularly shaped tubes that cannot be automated for batch cutting. It can improve work efficiency by 5-6 times. It is a must-select for tubes and profiles manufacturing companies to change production processes and reduce production costs and increase production volume. This equipment can be widely used in the cutting and processing of pipe structural parts in machinery, petrochemical, construction, shipbuilding bridge towers, and metallurgical pressure vessels.

Features:

1.Provide a variety of lead-in and lead-out compensation methods to effectively solve the quality problem of overburning and leaving marks at the cutting point

2.Provide the pre-processing function of the CNC program, compress and fit the small line segments in the DXF arc into a smooth curve, make the CNC square tube cutting machine cut smoothly, effectively avoid the machine shake up and down, improve the cutting quality

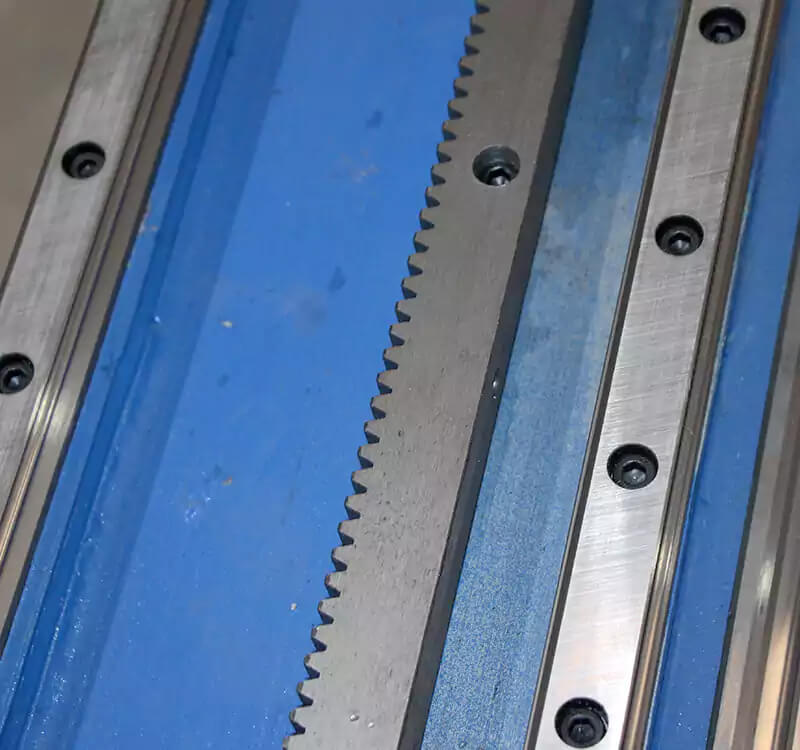

3.Provide automatic cutting process of gear rack gap compensation, effectively solve the cutting quality problem of the reverse gap

4.Effectively solve the problem of corner overburning and tilting of arc cutting surface.

Technical parameters:

| Project | Parameter |

| Square tube cutting diameter | Weight = 80 ~ 400mm |

| Cutting method | Flame / plasma |

| Flame cutting tube wall thickness | Vertical cutting 6 ~ 60mm bevel cutting 6-40mm |

| Plasma cutting tube wall thickness | Vertical cutting 1 ~ 25mm groove cutting 6-18mm |

| Effective cutting length | 12000mm |

| Required workpiece ovality | ≤1% |

| Cutting speed | 10 ~ 200m / min |

| Moving speed | 10 ~ 6000 mm / min |

| Torch axial swing angle | a = ± 65 ° |

| Cutting torch radial swing angle | β = ± 65 ° |

| Acceptable temperature around | -20 ℃ -50 ℃ |

| frequency | 5012 / 601Z |

| Cutting precision execution standard | According to international standards IS09013-2002 and IS08206-1991 |

| Chuck nature | Manual 3-jaw linkage self-centering |

| Manual chuck tightening device | 1 set |

| Cutting length accuracy | 土1.5mm |

| Machine color | Corporate color |

| Weight of pipe to be cut | 5000Kg |