position: HOME > PRODUCTS > Circular Seam Welding Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

Product introduction:

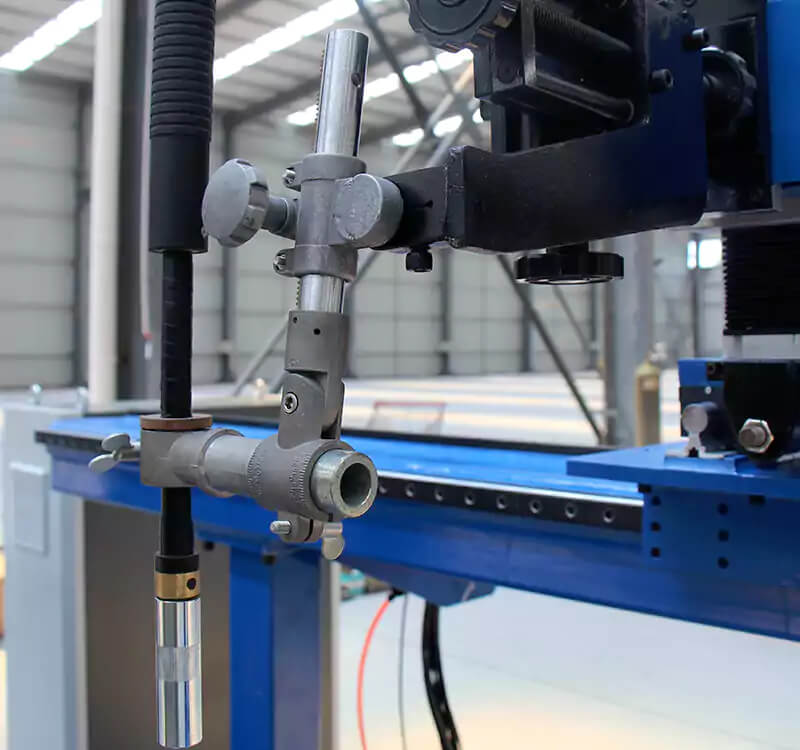

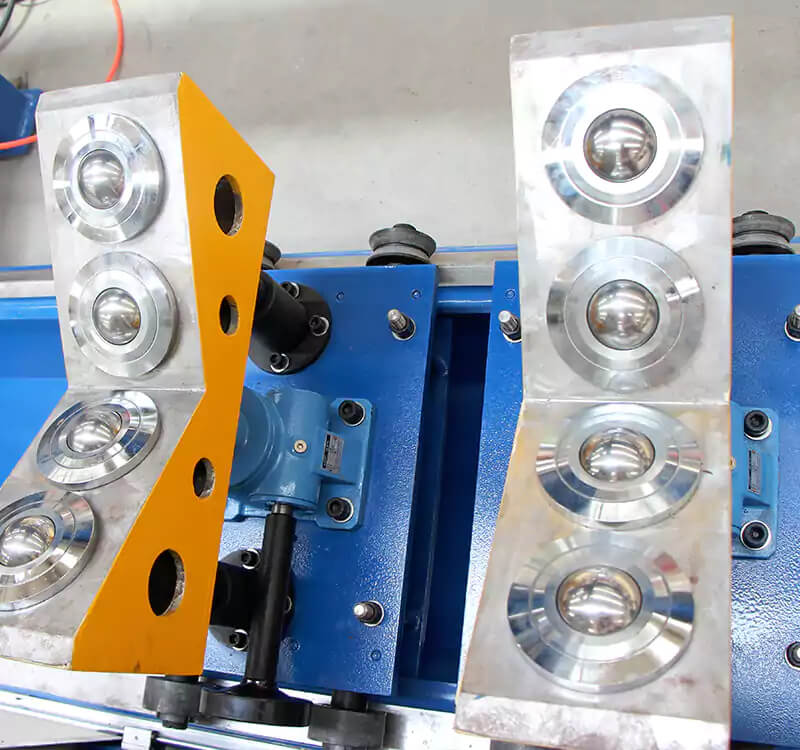

According to the condition of the workpiece, the MIG welding process is adopted, which has the characteristics of high quality of the weld, beautiful appearance of the weld, easy observation of the welding process, and few welding defects. Open a single 35 ° bevel and leave a 2mm blunt edge. Generally, manual argon arc welding is used as the introduction, and then it is used to fill the surface of the workpiece to ensure the appearance and appearance. For fillet welds, welding is generally performed in a horizontal position. If the size of the workpiece is short (less than 500), the workpiece can be welded at an angle of 45 degrees. For internal fillet welds, the side of the clamped steel pipe is welded horizontally.

The use and application equipment:

Application: 304 stainless steel longitudinal and circumference seam welding; cylinder diameter: Ф400mm-Ф1200mm; cylinder length: L≤2500mm; cylinder wall thickness: δ2mm~δ6mm.

Job-status: workpiece welding surface is smooth, the largest seam gap less than 2mm.

Condition of workpiece surface: no pollution, serious corrosion, etc.

Workpiece state before welding: before welding, workpieces are firmly spot welded, the joints are clean.

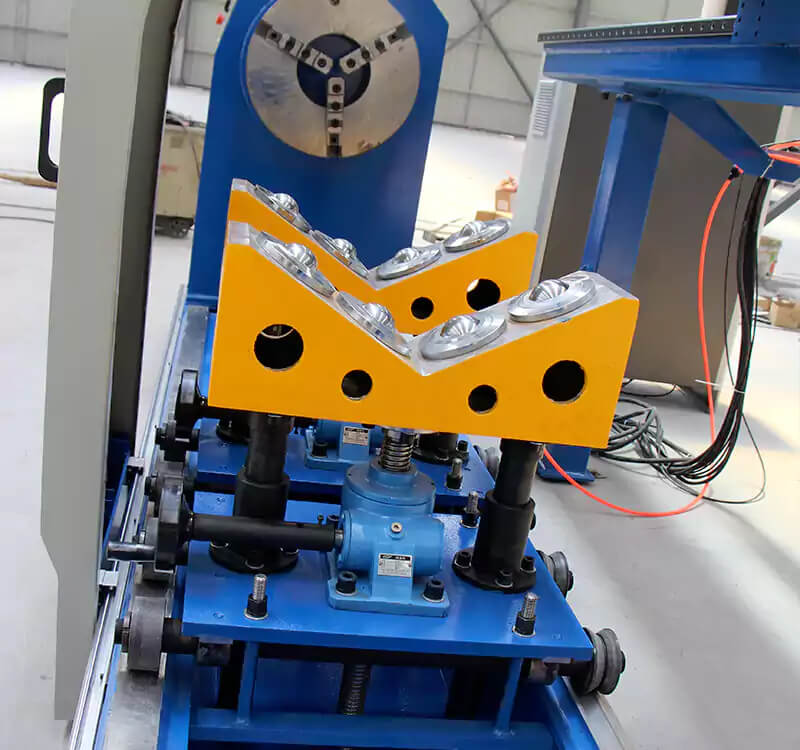

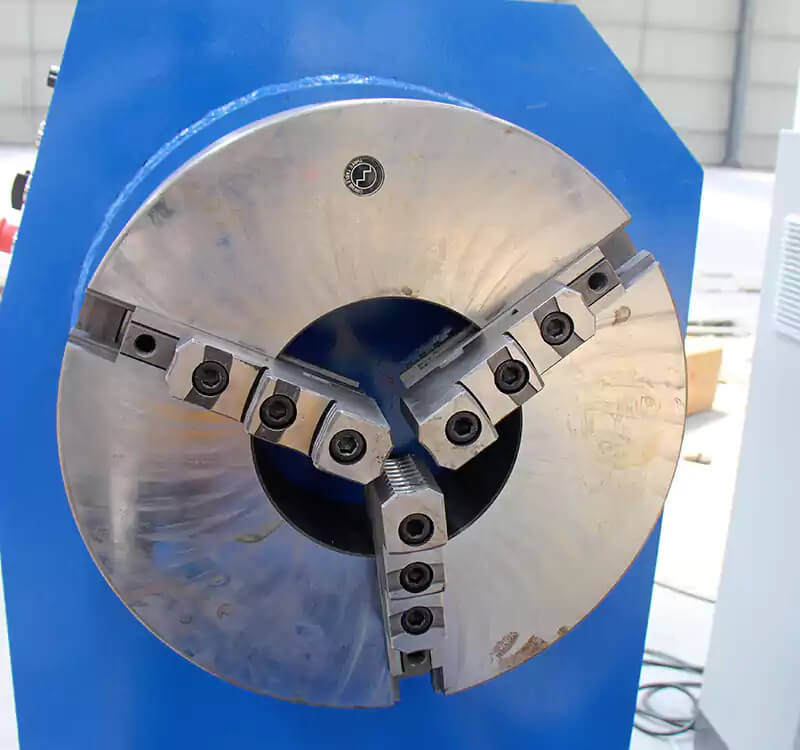

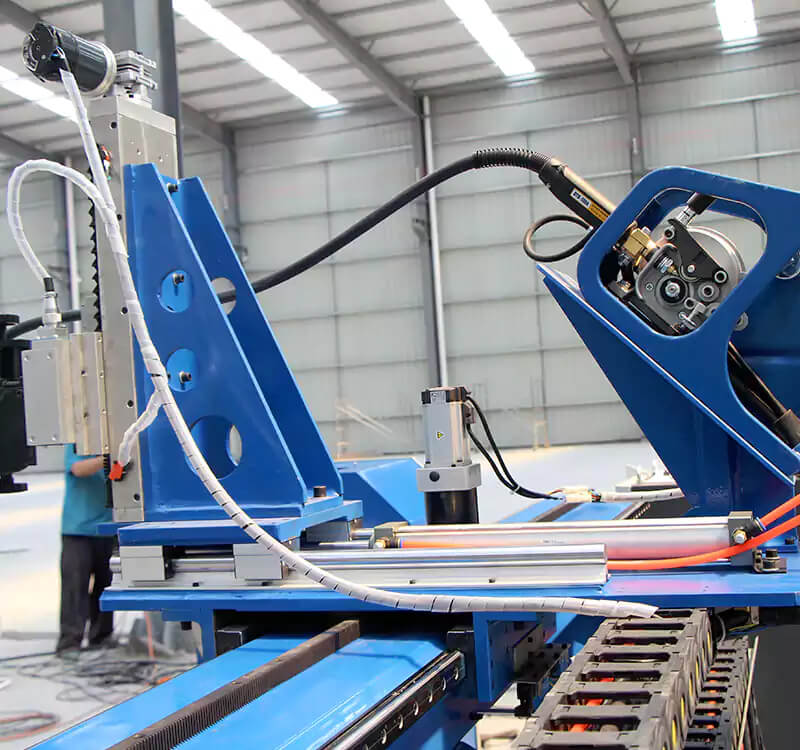

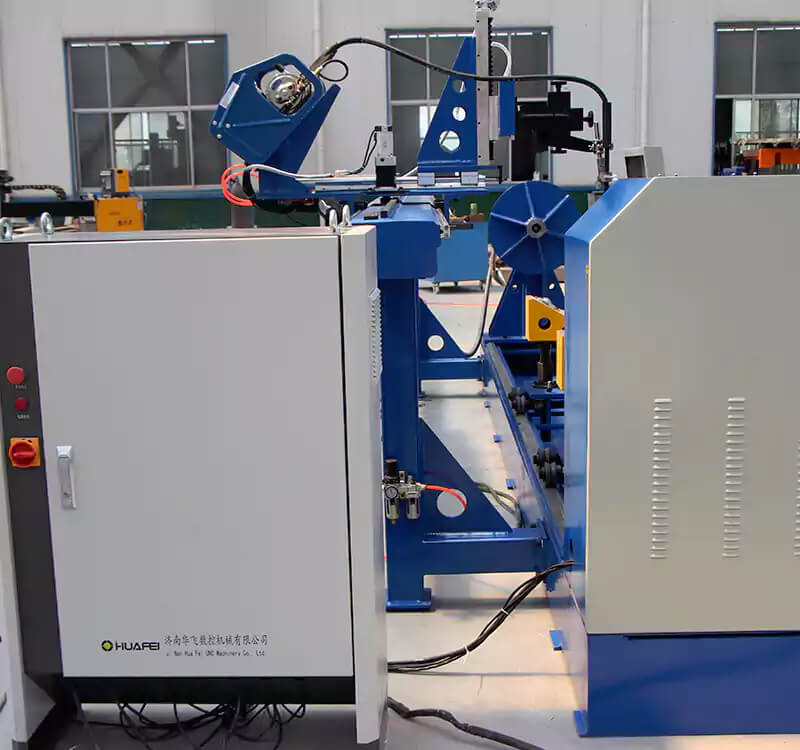

The equipment pneumatically clamps the head and tail of the workpiece and turns the workpiece automatically. Flanges are welded on a welding positioner (show in the picture). Two sets of the system are using one power source, and the equipment can realize the switch between different welding spots.

Advantages:

The welding surface of the workpiece is flat, the maximum gap of the butt weld is less than 1mm; no oil pollution, severe rust, etc.