position: HOME > PRODUCTS > Welding Positioner

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

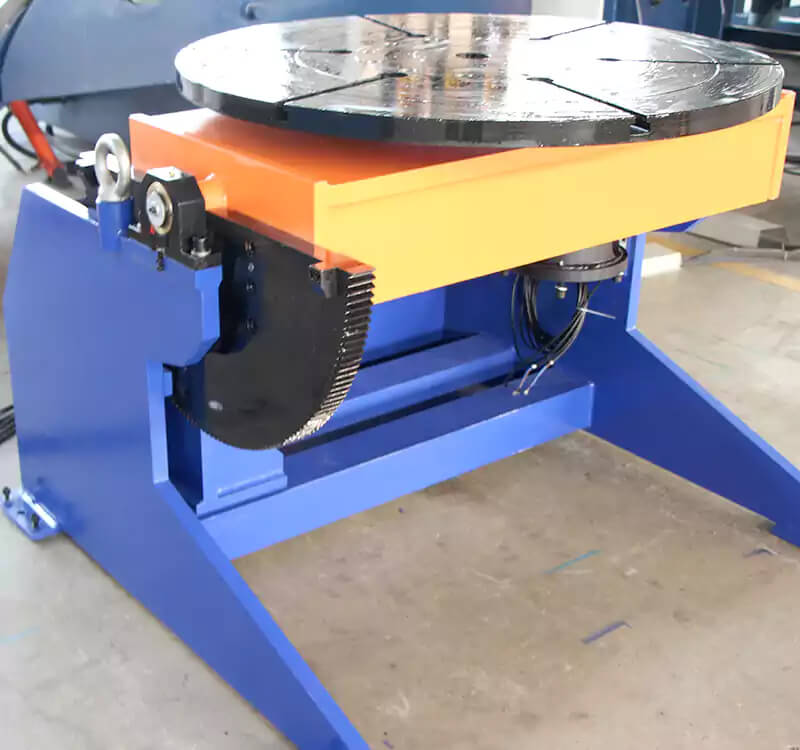

The welding positioner is a practical auxiliary positioner. It is mainly used in workplaces such as welding of steel structures and assembly of mechanical parts. It is widely used in the manufacturing industry of various steel structures such as flanges, pipe joints, etc. It can also be used as peripheral equipment and a robot to achieve automatic welding. It is one of the commonly used equipment in modern pipeline, container, and steel structure manufacturing enterprises.

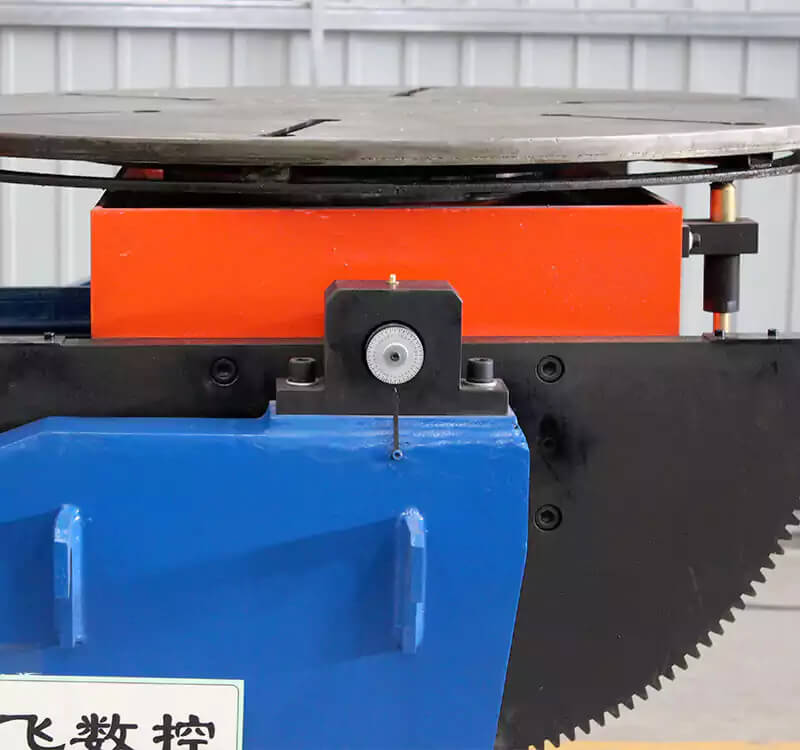

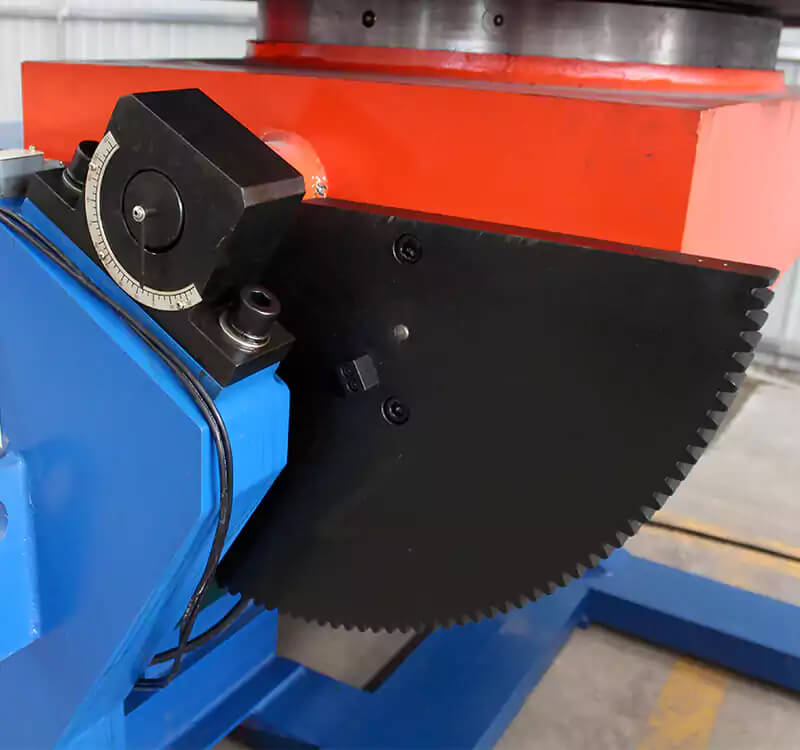

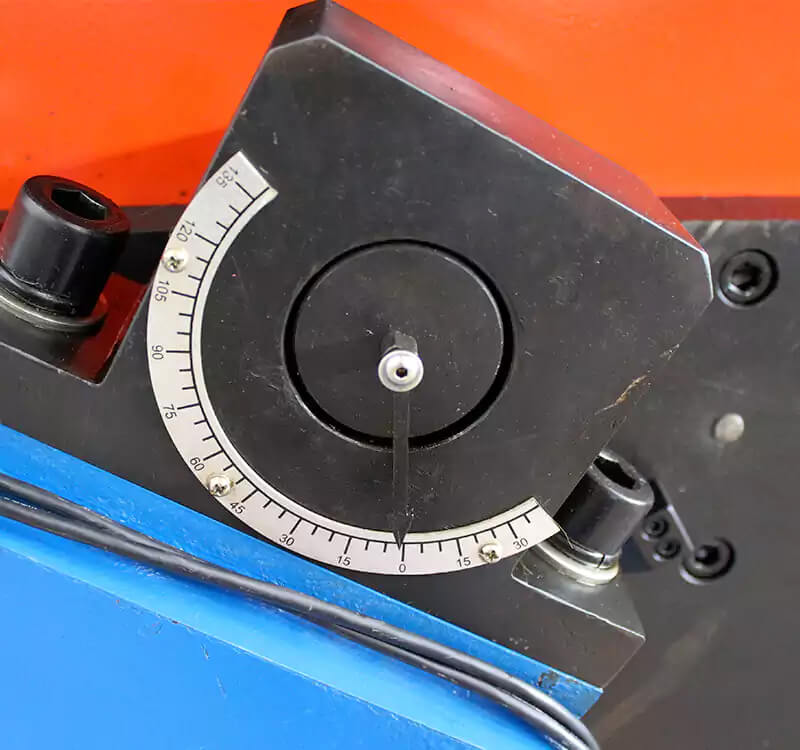

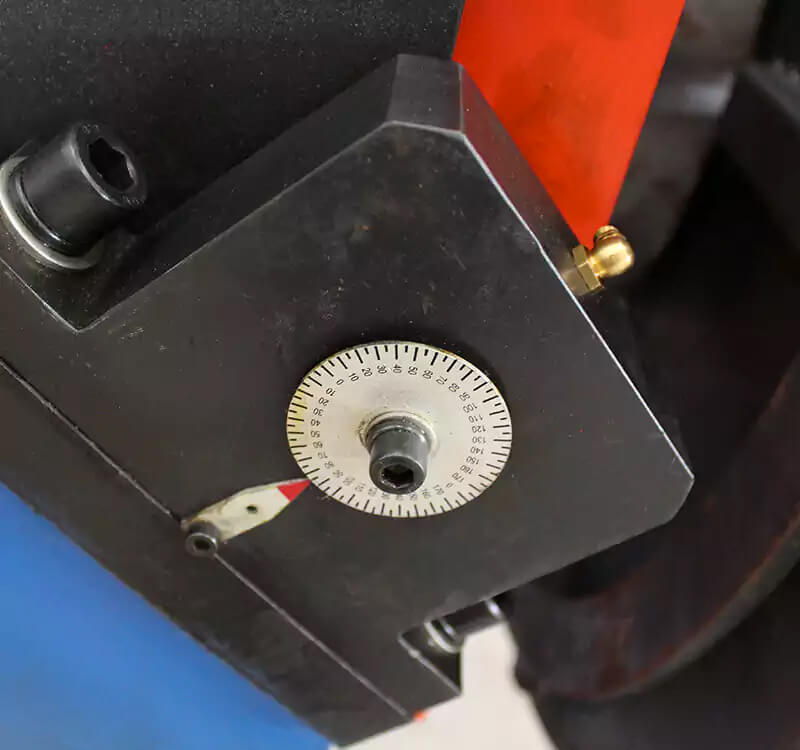

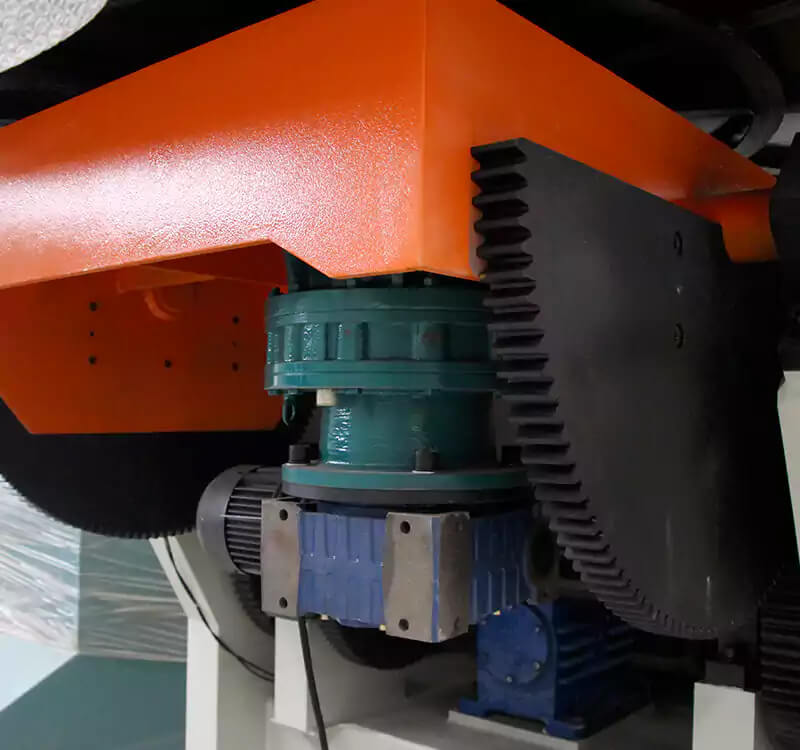

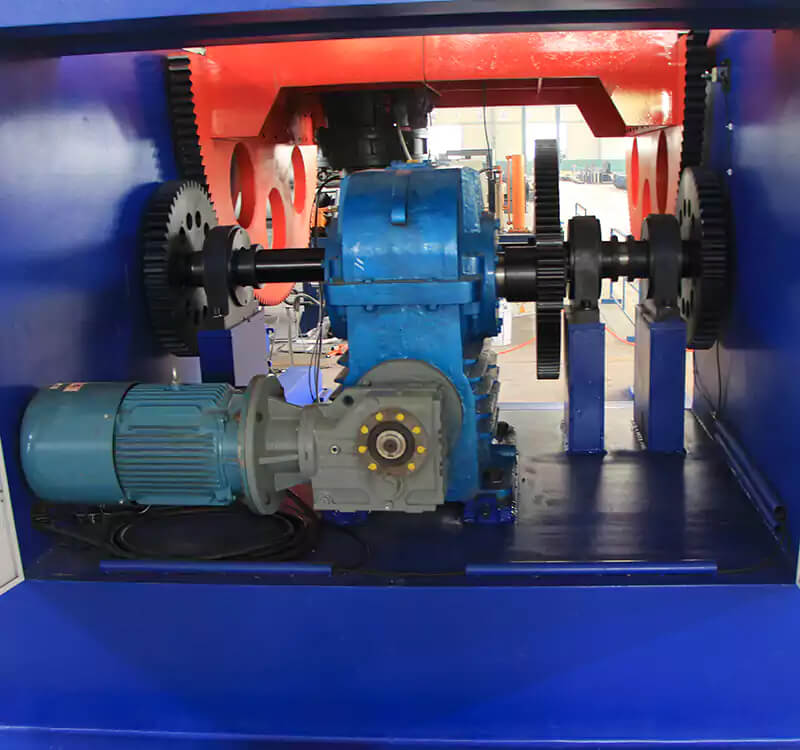

The seat-type positioner is composed of a rotating mechanism, a turning mechanism, a frame, and an electronic control system. It rotates and flips the worktable to make the workpiece in the optimal welding or assembly position. The rotation of the worktable adopts stepless speed regulation by frequency conversion. The worktable is driven to tilt by sector gear or hydraulic cylinder. The rotation angle of the worktable is 0 ~ 120 °. It can realize joint control with an operation machine or welding machine. The control system can be configured with three types of configurations: push-button digital control, switch digital control, and switch relay control.

The seat positioner can be used with various automatic welding or manual welding, can be used for pipe and pipe butts welding, pipe end welding, and various shafts, disks, cylinders, and other workpieces. It has a compact structure, beautiful appearance, and convenient operation. Etc. The seat positioner is currently the most widely used structural form. In production, it can not only improve the welding quality, but also reduce the number of work transfers, reduce labor intensity, and quickly improve production efficiency.

Features:

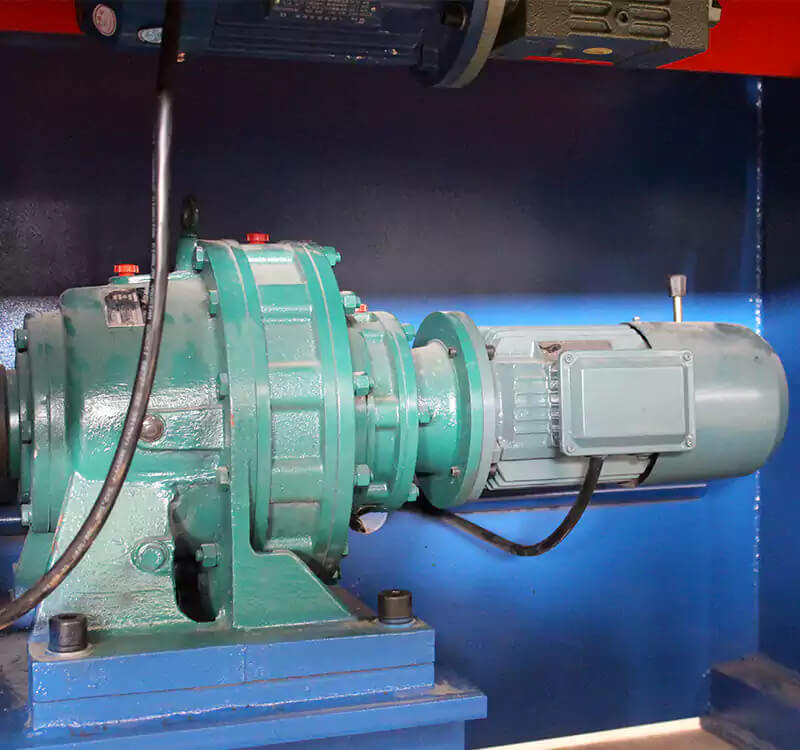

1. Variable frequency stepless speed regulation.

2. Can turning freely.

3. Wide applicability.

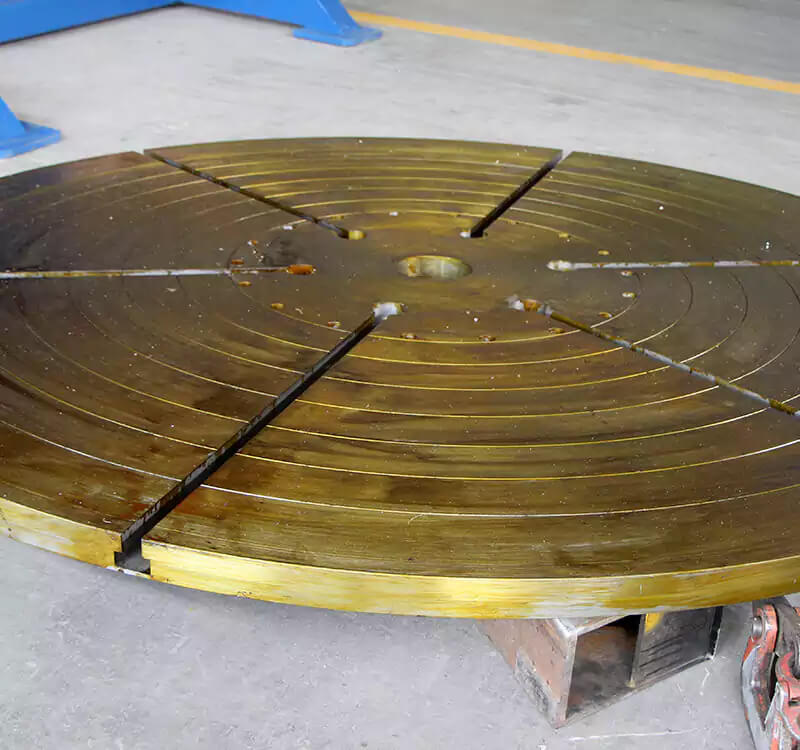

4. The work surface is made by precision machining of castings, which is not easy to be damaged by welding spatter.

5. The body adopts a seat structure, and the overall stability of the equipment is good.

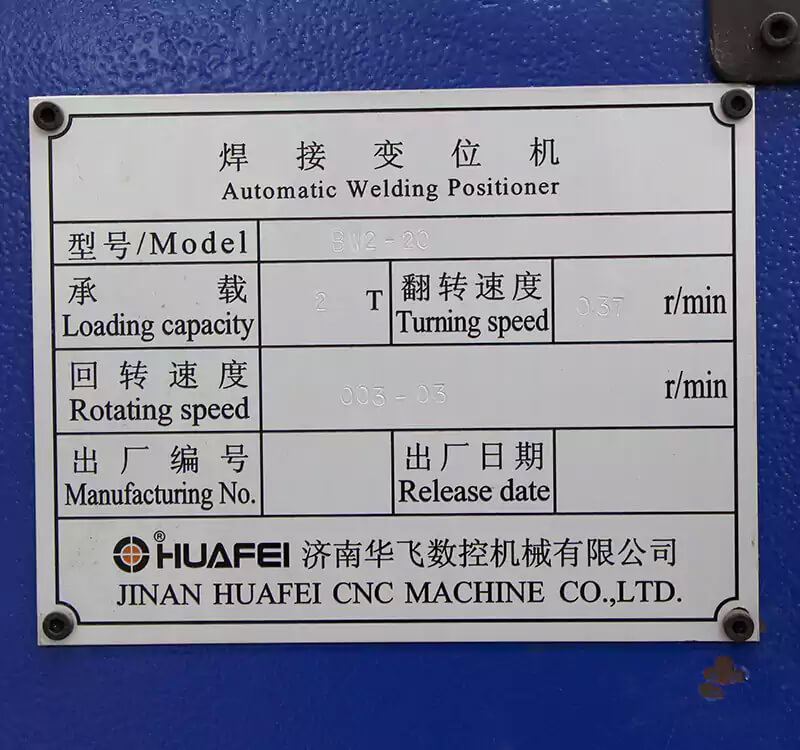

Technical parameters:

| Model No. | BW2-10 | BW2-20 | BW2-30 | BW2-50 | BW2-100 | BW2-150 | BW2-200 | |

Basic loading (kg) | 1200 | 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | |

| Rotating speed(r/min) | 0.1~1 | 0.1~1 | 0.06~0.6 | 0.05~0.5 | 0.05~0.5 | 0.02~0.2 | 0.02~0.2 | |

Overturning speed(r/min) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.15 | 0.2 | |

| Turning angle(°) | 120 | |||||||

Work table diameter(mm) | 1000 | 1100 | 1400 | 1600 | 2000 | 2200 | 2500 | |

| Height of work table(mm) | 1100 | 1200 | 1500 | 1550 | 1900 | 2000 | 2100 | |

Allow work piece off-center(mm) | Eccentricity | 150 | 150 | 200 | 200 | 200 | 200 | 200 |

Centroidal distance | 250 | 250 | 300 | 300 | 400 | 500 | 600 | |

| Rotating motor power(kw) | 0.75 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | |

| Turning mootr power(kw) | 0.75 | 1.5 | 1.5 | 3 | 4 | 5.5 | 7.5 | |