position: HOME > PRODUCTS > Circular Seam Welding Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

Product Introduction:

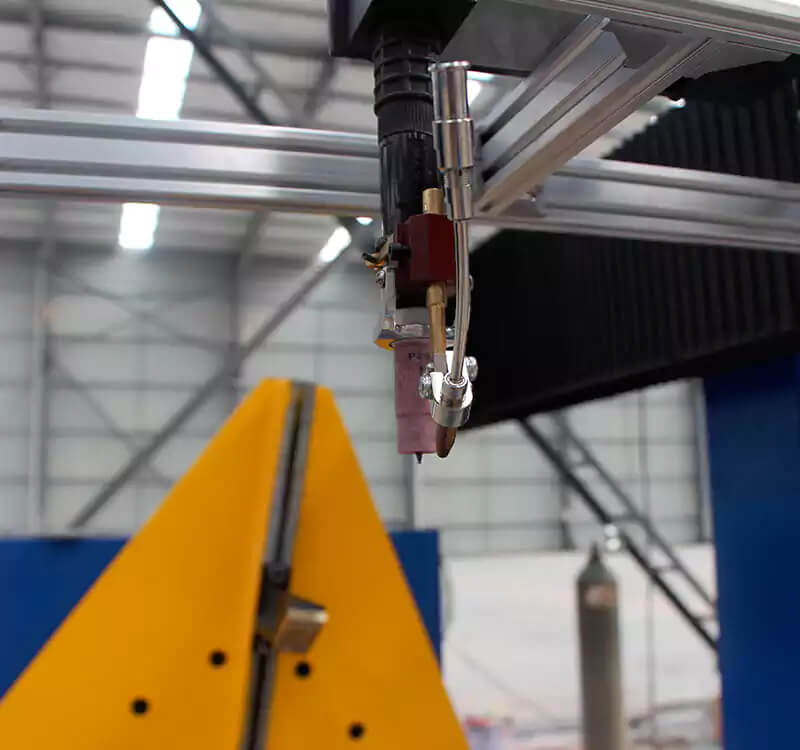

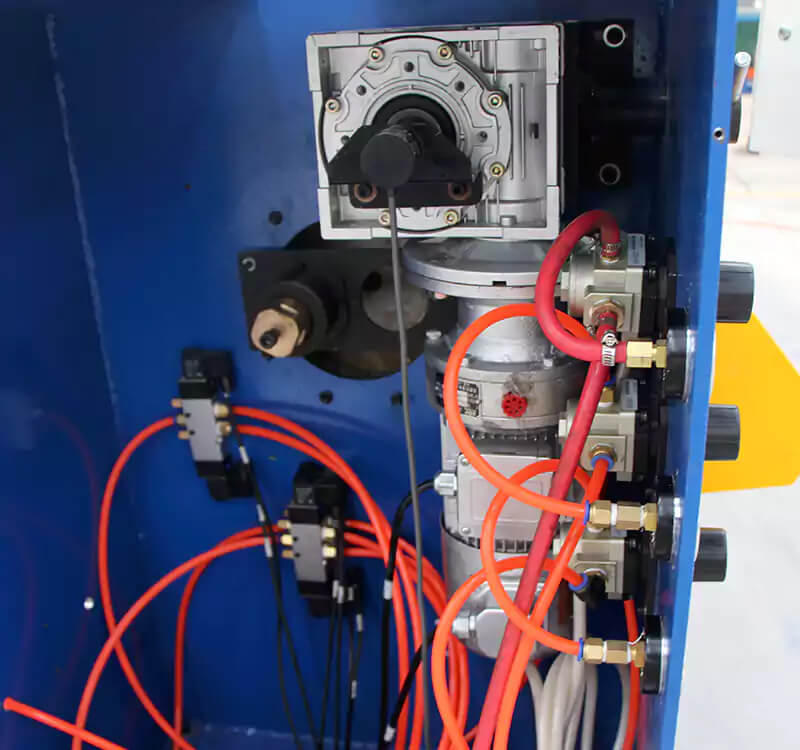

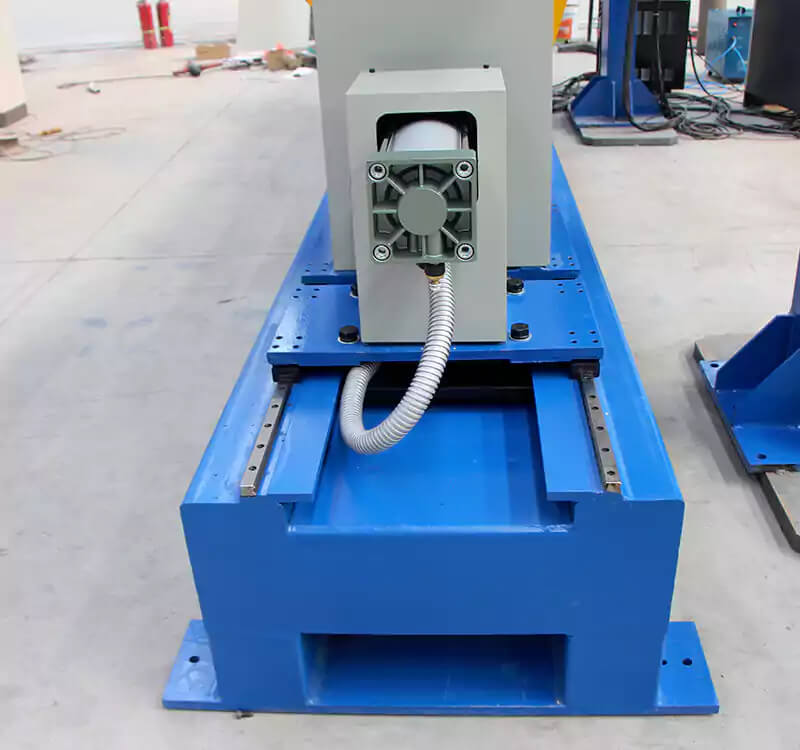

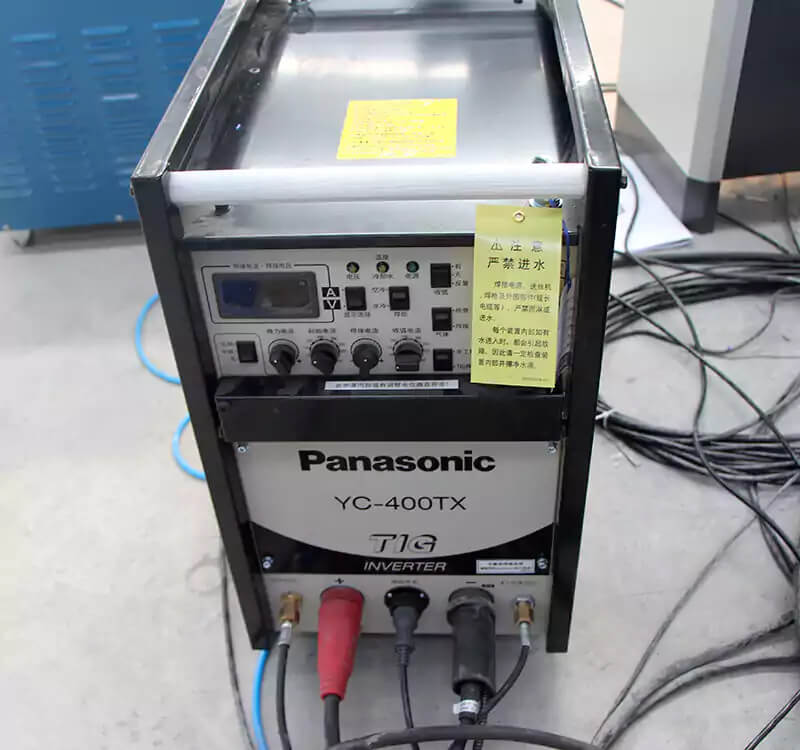

Hydraulic cylinder ring seam welding equipment adopts industrial PLC, touch human-machine interface, servo motor, and AC inverter to realize automatic welding. It is mainly used for automatic multi-layer swing welding of circumferential seams of hydraulic cylinder bodies and living: the equipment uses horizontal The structure of the bed, the axial movement of the welding head is driven by a servo motor: to adapt to the welding of workpieces of different lengths, the tailstock is moved manually and pneumatically. The welding seam is beautifully formed, uniform, and has a deep and wide melting range. The welding machine is flexible and simple to operate, the workpiece is conveniently clamped, the performance is reliable, the loading and unloading are convenient, the degree of automation is high, and the labor intensity of the worker is low.

Advantage:

1. The industrial PLC is used to control the whole machine operation, the control is accurate and reliable, and the operation is simple and convenient.

2. Adopt AC frequency converter to adjust the speed, realize the stepless adjustment of welding speed, and the adjustment is convenient and reliable, the adjustment range is large, the accuracy is high, and the operation is stable and reliable.

3. Using the high-definition color touch screen, it is convenient to set various welding process parameters.

4. Abundant welding process parameters to realize full-function automatic welding.

5. Using high-quality water-cooled push wire welding torch.

6. Adopting mechanical positioning, pneumatically tightening the workpiece, positioning is accurate.

7. The welding gun swings during the welding process, and can realize the multi-layer automatic welding process of surface surfacing welding and bevel surfacing welding.

8. Powerful process integration, users can choose flexibly according to workpiece welding requirements.

9. Improved work efficiency and reduced labor intensity.

Product parameters:

| Input voltage | 3-phase 5-wire AC 380V /220V 50Hz |

| Input capacity | 35.8KVA |

| Welding speed | 0.2~2r/min |

| Rated output voltage range | 15~50V |

| Rated output current range | 60~630A |

| Output no-load voltage | 70V |

| Rated input current | 54A |

| Total motor power | 2KW |

| Welding gun angle | Adjustable 0-90 degrees |

| Welding gun up and down adjustment | 80mm |

| Adjustment amount of welding gun left and right | 80mm |

| Wire diameter | φ1.0~φ1.2mm |

| Workpiece diameter range | φ100-φ600mm |

| Workpiece length range | ≤2000mm |

| Welding method | Multi-layer swing or Step by step, spiral |

| Mixed gas | CO2+Ar |