position: HOME > PRODUCTS > Overlay Welding Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

Product introduction:

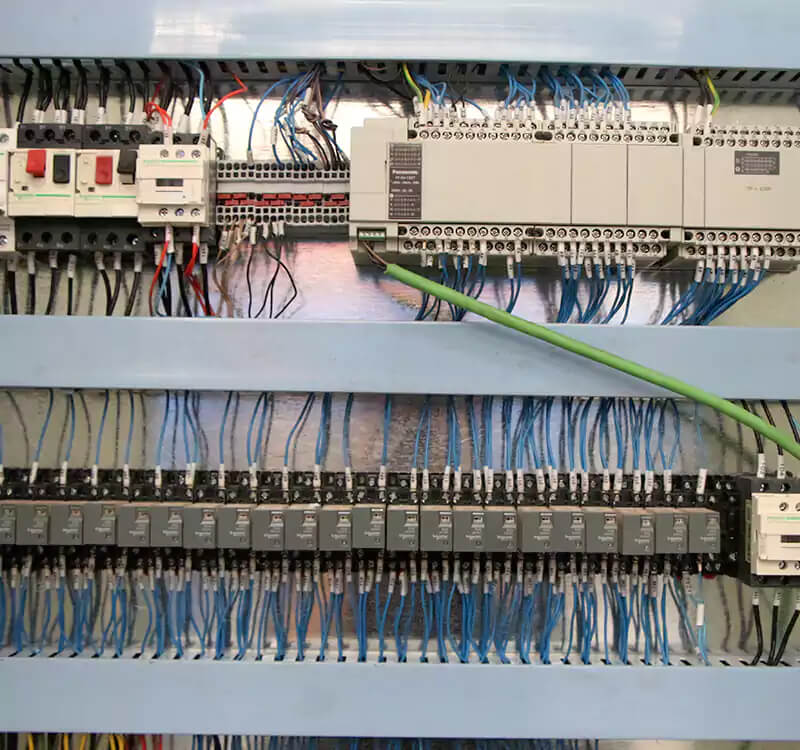

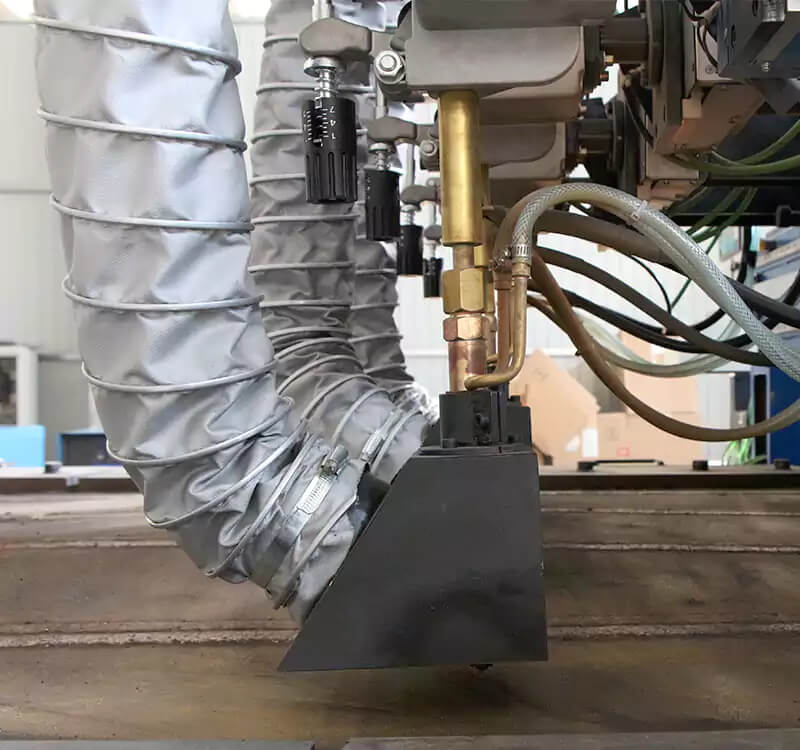

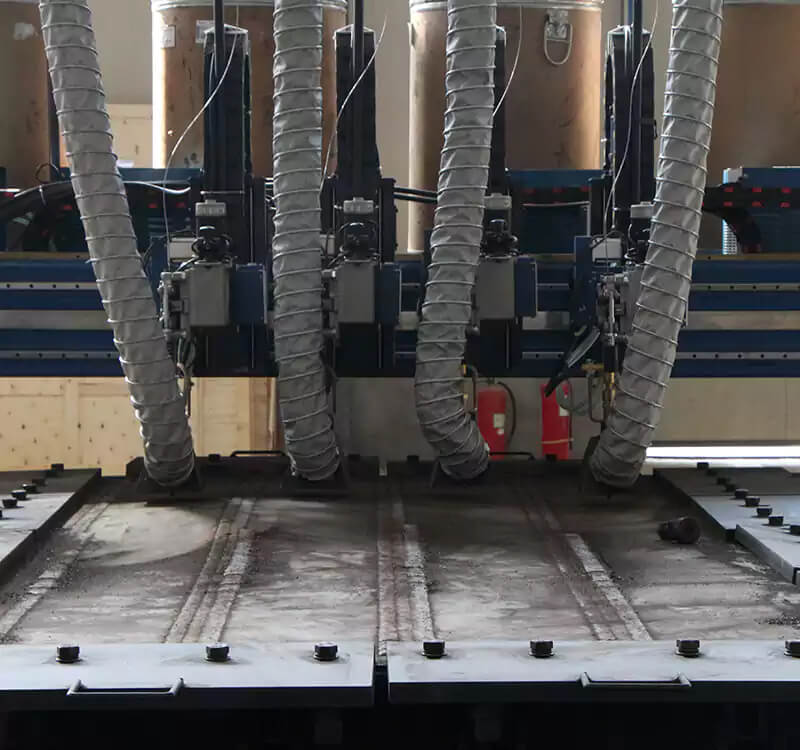

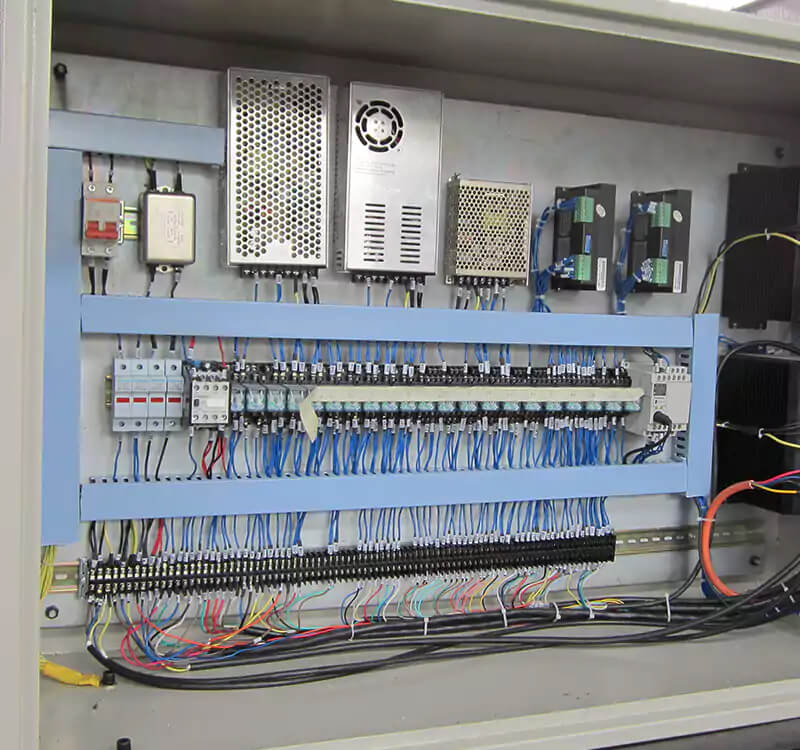

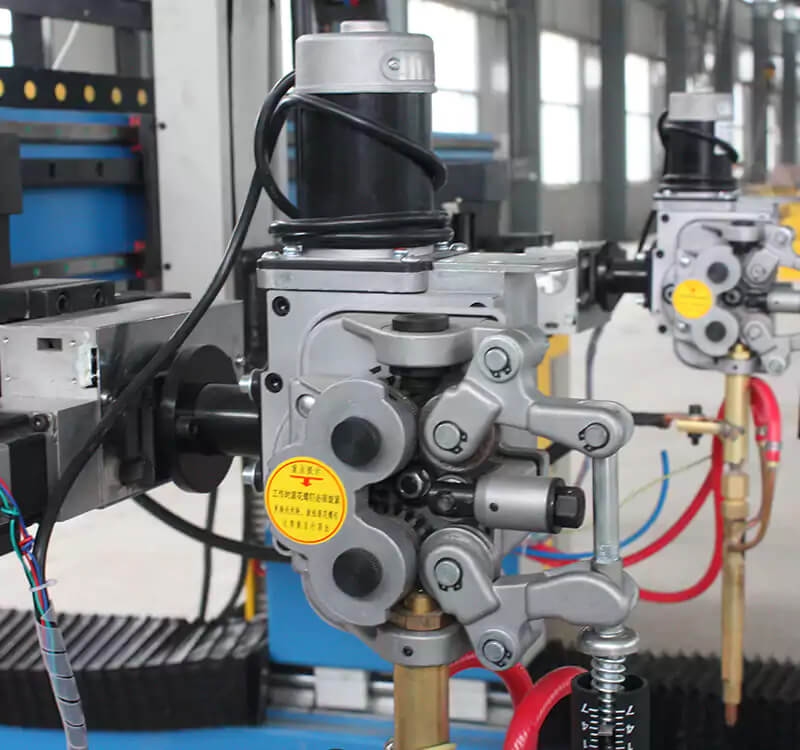

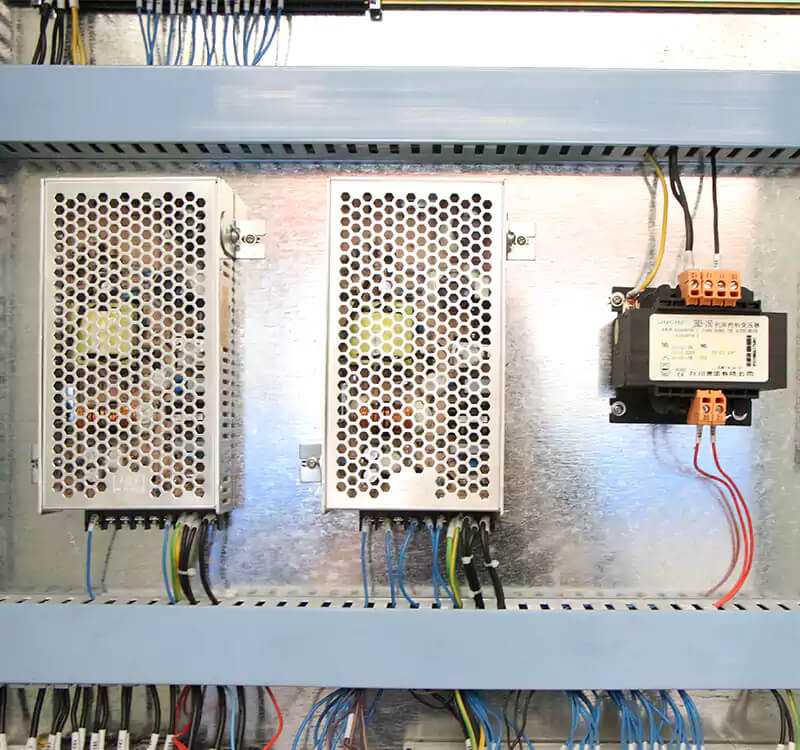

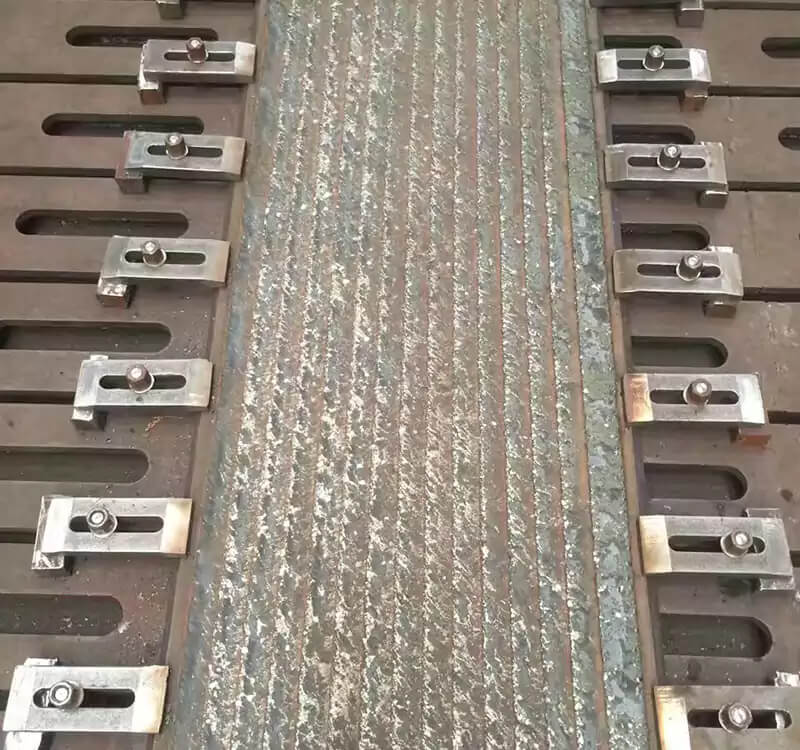

Wear-resistant compound steel plate is made by overlaying a wear-resistant alloy on steel plate surface with high hardness open arc welding wire. Its working principle is: lay workpiece on the carrier; welding arm provided with an open arc welding head on the gantry frame, moves horizontal and vertical so that the welding nozzle align at the seam, and then gantry frame walking on the rail straightly, to carry on automatic welding, the welding seam machine can weld 2-4 seam at the same time. The wear plate surface overlay welding machine is composed of a gantry type welding machine, automatic submerged arc welding power supply, wire feeding machine, water-cooled torch, inner circulation water cooling machine, water cooling circulation platform, smoke purifier (optional) and others.

Features:

1. High wear resistance: The thickness of the wear-resistant layer of the wear-resistant steel plate is 3-12㎜, and the hardness of the wear-resistant layer can reach HRC58-62. The wear resistance is more than 15-20 times that of ordinary steel plates and 5-10 times more than that of low-alloy steel plates. It is high chromium cast iron. The wear resistance is more than 2-5 times, and the wear resistance is much higher than spray welding and thermal spraying.

2. Good impact performance: The wear-resistant steel plate is a double-layer metal structure. The wear-resistant layer and the substrate are metallurgical. The bonding strength is high. It can absorb energy during the impact. The wear-resistant layer will not fall off. It can be applied to strong vibration and shock. Under the working conditions, this is inferior to casting wear-resistant materials and ceramic materials.

3. Good temperature resistance: Wear-resistant steel alloy carbide has strong stability at high temperatures. Wear-resistant steel can be used at 500 ℃. Other special requirements can be customized. It can be used under 1200 ℃. Abrasion-resistant materials such as molecular materials can not meet such high-temperature requirements.

Product parameters:

| Effective transverse welding stroke | 1500mm; Can be customized |

| Effective longitudinal welding stroke | 3000mm; Can be customized |

Welding speed | 150-1500mm /min |

Gantry gauge | 3000mm |

| Cross slide trim trip (Electric) | 60mm |

Welding torch up and down stroke (Electric) | 260mm |

| Swing speed | 0-2400mm/min |

Longitudinal servo motor power | 0.75kw |

| Horizontal servo motor power | 0.75kw |

Power-driven planker speed up/down | 200mm/min |